Though they may be small, the fittings, connectors, and couplers you use with an air hose play a big part in how air compressors work. They ensure that airflow remains constant through these tools, allowing them to work efficiently and guarantee the safety of anybody operating them in the meantime.

That’s why it’s so important to understand how they work. If you want more information, you should check out this guide to air hose fitting and coupler types when you can. In the meantime, here are some tips of our own!

Air Fitting Measurements

Hose fittings come in a wide variety of sizes depending on the hose and the type of air compressors you’re working with. So, with that in mind, you’ll need to make sure the end fitting and any couplers used are the same size so that they are compatible.

The main measurement is hose circumference. This dictates what size coupler and end fitting you’ll need to get. Sometimes diameter is important too, in which case you just need to divide the circumference by Pi (that’s 3.14). You can figure out both the circumference and diameter by following these steps:

- Wrap a length of string around your hose, keeping it as straight as possible.

- Mark both ends of the string

- Remove the string and measure between those points.

- You now have the circumference of your hose.

- Then divide that figure by Pi.

- That’s the diameter of your hose.

Fortunately, many air tools have standardized the sizes of their end fittings, so you shouldn’t have too much trouble finding a compatible match. Instead, you’ll need to pay more attention to the fitting type and thread size instead of the end fitting size.

Read on to find out more about fitting types.

BSP Fittings

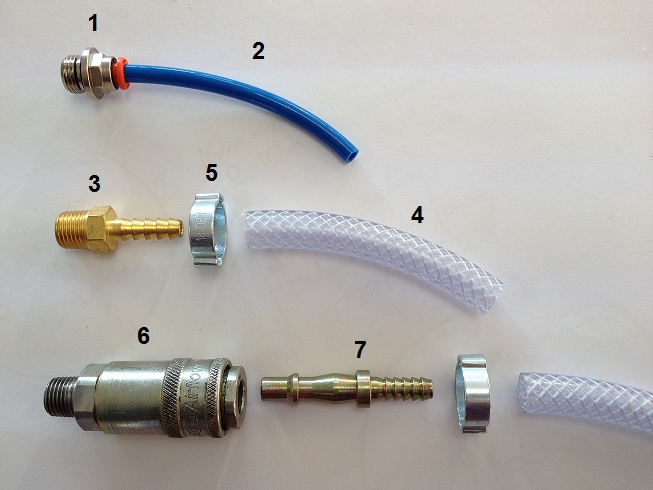

The most common types of air tool fittings are BSP and PCL.

BSP stands for British Standard Pipe and is a type of screw thread that is used internationally. It connects and seals pipe ends by joining male ends to female ends. Where BSP couplers are sold, they will have an M or an F next to them which lets the buyer know that they are compatible with a male or a female connection.

PCL Fittings

PCL couplings are a type of connector that looks similar to BSP fittings, though they are not compatible. They connect through a moveable collar that is pulled back while used with an air tool to disconnect. Doing this allows compressed air to escape, though this can cause the hose to shift where it can damage nearby objects. They work best as a single-action coupling in a fixed application like attached to a compressor.

Connecting Hoses

High-quality air hoses predominantly feature threaded or quick-release couplings, distinguished as male or female, ensuring compatibility solely with their counterpart fittings. One must employ a collar to merge two lines to facilitate hose interconnection.

Prioritizing hoses with enhanced resistance is advisable, given their prolonged lifespan and inherent capability to endure long wear, thereby minimizing replacement intervals. Superior-grade hoses guarantee consistent operation and forestall unforeseen malfunctions. An investment in such hoses not only ensures operational safety but also augments cost efficiency over time.

While couplings grant the flexibility to extend hose length, spatial constraints, and budgetary considerations are limiting factors. Notably, a network of interconnected hoses may exhibit reduced strength compared to a singular extended hose, as each juncture potentially introduces a pressure diminution.

Quick-Release Couplers

Where you may be connecting and disconnecting hoses and fittings frequently, quick-release couplings are the best. Each coupling uses a male and female part that connects and forms a sealed bond, so no shut-off valve is needed. These couplings can also move without twisting or kinking the hose. This is better for workplaces where the hose may get moved more.

Remember that couplers come with different temperature and air pressure ratings for the environments they’re working in.

Using Tape On Air Fittings

To reinforce threaded fittings, some apply Teflon tape to them. If you’re using high-quality fittings, they are internally sealed with o-rings and other mechanisms that are much more effective than tape, so you’d usually be wasting your time.

Any leaks will come from an o-ring being damaged or disconnected entirely due to incompatibility. Replacing the problem fitting shouldn’t be too much trouble and will be more effective than any tape.

Conclusion

Those are some of the basics about air fittings, hose connectors, and quick-release valves. By knowing how they work, any jobs you do with air tools, air compressors, and air hoses will go more smoothly. As always, remember to consult manuals and user guides for any tools and parts that you use.