Jobs associated with electricity are sometimes dangerous, and they raise concerns for safety. For instance, the workers are exposed to electrical shocks, burns, and fatal electrocutions. Therefore, safety should be treated as the highest priority in the power industry. Here are 6 important things to invest in to ensure safety and quality when you run an electrical business.

1. Personal Protective Equipment

You should invest in personal protective equipment to protect the employees from performing different tasks in your firm.PPE must be your first line of defense against shocks and other potential hazards that may happen on the job. The quality of appropriate gear for each employee depends on their exposure to risk. When working in the electrical industry, you should always wear safety boots and electrical gloves to protect you from risks that can occur from random workplace accidents. You should also use a fire-resistant helmet, goggles, and ear protection to ensure safety when you work with wiring.

2. Quality Control and Testing

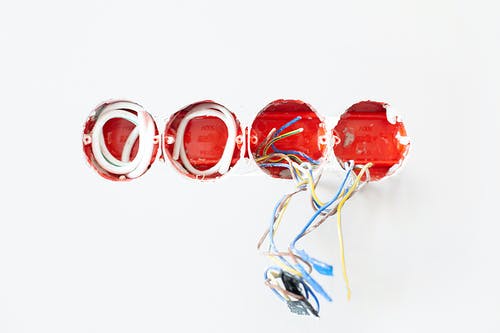

Your design process of harnesses should always follow the expected standards. In every procedure, there are different steps you should take to ensure that you produce quality products. There are people that provide services that specialize in all kinds of wiring, and the services provided at Allplant wiring harness design give you insight into how they go through the testing process and quality control, and why it’s important. Initial testing should involve elements like checking lengths, connectors, and correct pinouts. A thorough inspection must be conducted once initial testing is complete. To achieve this, you must use the right testing equipment for each process. Remember to use approved equipment to prevent shocks or electrocutions. You must not leave anything to chance since this can be very dangerous. You need to get high-quality equipment like voltage detectors, receptacle testers, and clamp meters.

3. Employee Training

Another critical aspect is to ensure that employees have proper training in the use of electrical equipment. Many business owners make the mistake of believing that their employees are professionals and overlook the need to constantly train them. The continuous use of the same equipment daily can lead to bad habits that will also cause improper usage. This kind of behavior can be very dangerous, so your workers must receive proper training to perform their duties safely. The workers should also understand how to use every tool to avoid harm. You must provide instructions for each piece of equipment and make sure the operators have appropriate qualifications.

4. Use Circuit Breakers and Volt Regulators

Voltage and circuit breakers are vital in any industry to improve safety. If there is a short circuit along with the electricity supply system, a circuit breaker as the name suggests breaks the flow of current. This will safeguard your appliances or equipment from damage. Additionally, circuit breakers are also designed to protect employees from electrical shocks or deadly electrocution. Voltage regulators also help prevent damage to your equipment during electricity surges. On the other hand, a surge protector is a great tool that shuts power during an emergency. No one will be exposed to harm when the power supply is shut. Make sure you fix the problem before restoring the energy supply.

5. Utilize Cord Protectors

When you use extension cords in your operations, make sure they are protected, and there are no naked wires that can cause electric shocks. Make sure your power cords run in safe areas where they are not exposed to rough surfaces that can cause damage. Cord protectors and cable covers are a good way to exercise safety in the workplace. It is essential to install floor cord protectors to prevent employees from tripping over loose wires. Encourage the workers to inspect all power cables before they begin work. All errors should be resolved quickly before they cause any harm.

6. Create a Conducive Working Environment

Make sure your workstation is safe and properly covered to protect equipment. Check the drainage around your working environment to ensure that it is free from water. Electricity and water don’t mix well since this combination increases the risk of electrocution when operating electrical equipment. The situation can be worsened by cables that are poorly insulated. Therefore, you should eliminate all wet conditions, and a licensed electrical contractor must inspect your plant regularly. You also need to renovate all structures showing signs of damage or aging to ensure maximum safety.

When you operate in the electrical industry, be sure to prioritize safety. Always encourage workers to wear protective gear and ensure the environment is safe. You can also follow these tips to boost your company’s efficiency, productivity, and overall level of safety.